Protective Film Of Color Steel Plate

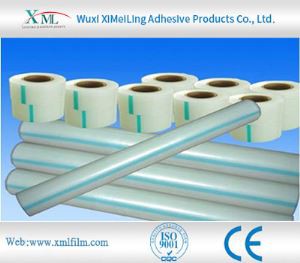

This protection film is a surface protective material using polyethylene as a base material. 100mm – 1700 mm widths and 100 meter – 2000 meter lengths. In addition, the color steel Sheet protection film comes in a variety of colors, with patterns and words printed on the surface if required.

Wuxi Xi Mei Ling Adhesive Products Co.,Ltd.

Wuxi Xi Mei Ling Adhesive Products Co.,Ltd. is located in the scenic coast of Taihu Lake, the birthplace of national industry and commerce, Jiangnan city of Wuxi. The company was founded in 2001, in the field of adhesive products we have many years of experience in the production of professional enterprises. The company provides a full range of protective film industry chain services, the production of various types of acrylic protective film, glass special protective film, aluminum plastic doors and windows profiles protective film, Stretch film, stainless steel color plate protective film, security door protective film, carpet Floor protective film, building decoration materials protective film, aluminum, household appliances, such as protective film products by all users of praise.

Why Choose US

Professional team

Our professional team collaborate and communicate effectively with one another, and are committed to delivering high-quality results. They are capable of handling complex challenges and projects that require their specialized expertise and experience.

Innovation

We are dedicated to improving our systems continually, ensuring that the technology we offer is always cutting edge.

One stop solution

We can offer a range of services, from consultation and advice to product design and delivery. It is a convenience for the customers, as they can get all the help they need in one place.

24h online service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

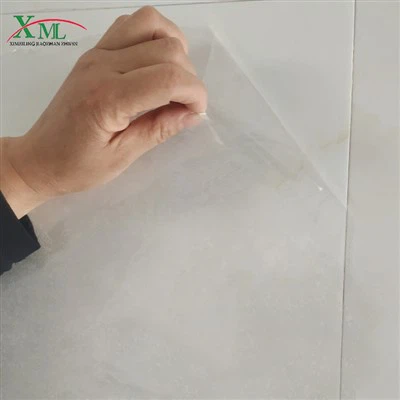

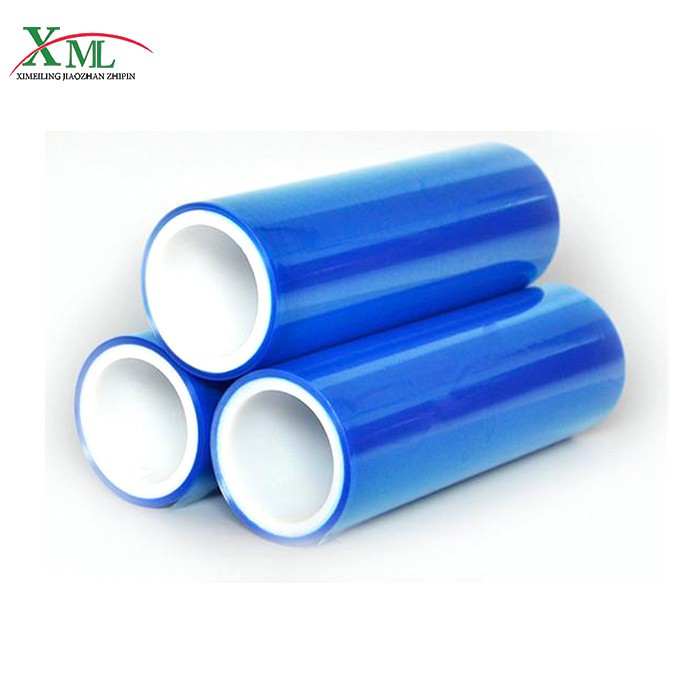

Glass Light Adhesive Protective Film

Glass light adhesive protective film When we produce and cut glass, the surface of glass will be scratched, glass light adhesive protective film can help us. It can protect windows, mirrors and high gloss surfaces from moving damage and paint oversprays.

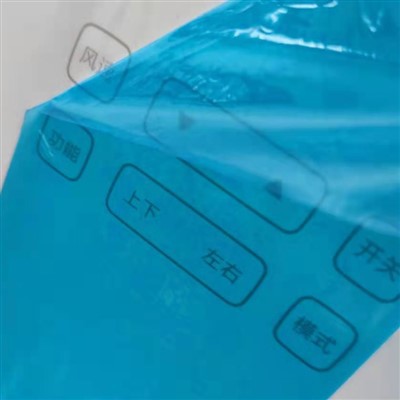

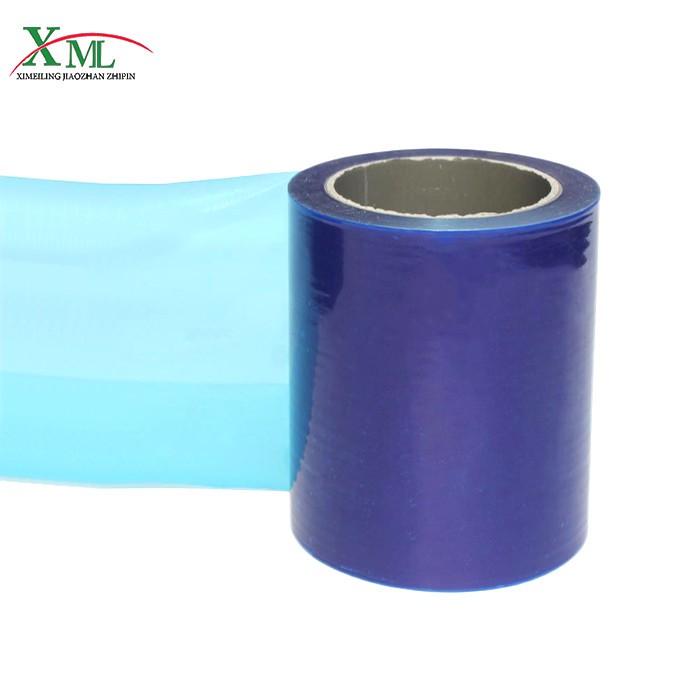

PE Protection Film For Electronics Devices

PE Protection Film For Electronics Devices protects electronic products from scratches, dirt and other damages, avoiding any unnecessary scratches or damages that may occur during transportation or daily use. The film maintains the visual clarity of the device, providing an unobstructed view of the screen while protecting the screen from fingerprints.

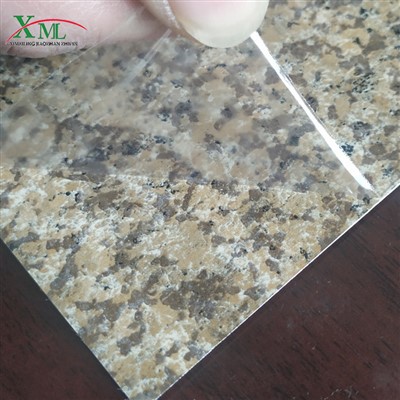

PE Protective Film For Ceramic

PE Protective Film For Ceramic protects marble and tile surfaces from dust, dirt and worker traffic during processing, transport and installation, retaining their original luster and protecting their quality from compromise, increasing customer satisfaction.

Plastic Printe Aluminum Protective Film

Plastic printe aluminum protective film Aluminum surfaces can be marred by chatter marks, scratches or swirls, or contaminated by overspray, solvents, dust and the like.

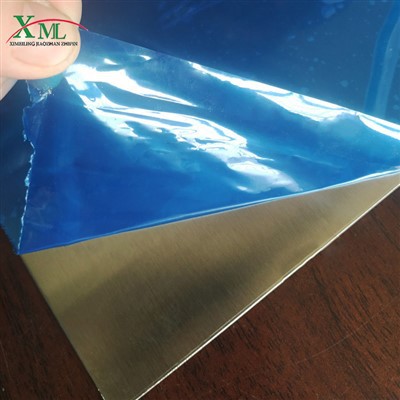

Protective Film Of Color Steel Plate

Protective Film Of Color Steel Plate is made of carefully selected high-quality materials, which can effectively protect the surface of color steel plate from scratches, dirt and other forms of damage that may occur during manufacturing, transportation and construction.

PE Protection Film For ABS Acrylic

PE Protection Film For ABS Acrylic is generally used on surfaces sensitive to adhesive or glue residues. Such as glass, lenses, high-gloss plastic surfaces, acrylic and other very smooth surfaces. No static can be felt on the outside of PE Protection Film For ABS Acrylic. It is a low adhesion self-adhesive film.

PE Protective Film For Mirror is very different from other surface protection films. Used on the back of a silver-plated glass mirror, it will not tear after installation, and can provide temporary protection for the mirror during transportation, storage, handling and installation.

Protective Film For Metal Surface

Protective Film For Metal Surface is an excellent way to keep metal surfaces clean, shiny and looking like new. When in use, it acts as a barrier between the metal surface and its environment, protecting it from dust, dirt, scratches and other forms of physical damage.

Metal Aluminum Alloy Stainless Steel Surface Protective Film

Metal Aluminum Alloy Stainless Steel Surface Protective Film Metal aluminum Alloy Stainless Steel surface protective film is dsigned to temporarily protect a variety of metal surfaces. It removes clean, without leaving any residue behind.

What is Protective Film Of Color Steel Plate

Color Steel Sheet Protection film offers good flexibility and ensures quick moistening of protected surface. The adhesive used has good stability, which guarantees the later, residue-free removal of the film. This color steel Sheet protection film can effectively protect metal plate surfaces from scratches and damage during storage, transportation, and further processing. This protection film is a surface protective material using polyethylene as a base material. 100mm – 1700 mm widths and 100 meter – 2000 meter lengths. In addition, the color steel Sheet protection film comes in a variety of colors, with patterns and words printed on the surface if required.

Advantages of Protective Film Of Color Steel Plate

Stable disengagement force

The change over time is small, that is, the lower the increase in disengagement force, the better

Suitable viscosity

Easy to stick and easy to tear

Long storage period

Stored in the warehouse for more than one year, no change in quality

Good aging resistance

Under the standard of sunlight exposure, the application time is as long as half a year to one year

No environmental pollution, no corrosion

The adhesive is lazy, and it is not easy to cause chemical changes with the surface of the material to be adhered

Good physical properties

Meet the customer's specified tensile strength, elastic mold, elongation, etc

The Importance of Color Steel Plate Protective Film

Protective film is a durable and strong film that protects color steel plates during different stages of transportation, handling, and installation. The protective film is an important part of ensuring that the color steel plate remains in its original condition during its service life.

First, the protective film provides protection during shipping. Color steel plates require long-distance transportation from manufacturer to customer. During transportation, it is exposed to various elements such as dust, debris, and moisture, which can cause surface damage. The protective film provides an extra layer of protection to protect the color steel plate from the elements and prevent any damage.

Secondly, the protective film protects the color steel plates during transportation. Color steel plate is a bulky material that requires special equipment to handle. During processing, there is a risk that the surface will become scratched or dented, which may affect the appearance and functionality of the material. The protective film acts as a buffer between the surface of the color steel plate and any handling equipment, ensuring that the surface remains intact.

Third, the protective film protects the color steel plate during the installation process. During the installation process, color steel panels are often exposed to harsh conditions such as extreme temperatures and sunlight. The protective film provides a barrier between the color steel plate and the environment, preventing any damage that may occur. In addition, it helps keep the surface of the color steel plate clean, reducing the need for cleaning during installation.

Finally, the protective film helps maintain the appearance of the color steel plate. Color steel plates are often used in building construction, and the beauty of the material is crucial. The protective film ensures that the color steel plate remains in its original condition and maintains its appearance for a long time.

In short, the color steel plate protective film is an important part to ensure that the material remains in good condition during transportation, handling, and installation. It provides shielding from the elements that can cause damage to the surface and helps maintain the appearance of the color steel panels. Therefore, it is important to ensure that the protective film is always in place before any treatment or installation is carried out.

How to Use PE Protective Film Correctly

PE protective film is as easy to apply as a piece of adhesive tape. However, as the protective film strips increase in width and length, the difficulty factor increases accordingly. Handling a tape that is 4 feet wide by 8 feet long is quite different than dealing with a tape that is 1 inch wide by 4 inches long.

A bigger challenge is to perfectly align the large-format PE protective film with the target surface without producing unsightly wrinkles or air bubbles on the surface, which is difficult to deal with on the surface of irregular products.

In order to better stick the protective film on the surface of the product and make it as perfect as possible, we need at least two people. One person holds the roll of protective film while the other pulls the torn end over the other end of the product to be protected, sticks the end to the target surface, and manually presses the protective film into place, toward the side holding the roll. people. This method is labor intensive and has low work efficiency, but the work effect is quite good.

Another way to manually apply large sheets of PE protective film to large sheets of material is to apply the material onto a film. You will need a roll of double-sided tape and a box cutter.

How to Perfectly Stick the Protective Film on the Surface of the Product

- Prepare a suitable large, flat workspace - larger than the object to be protected - clean and free of dust, liquids or contaminants.

- With the adhesive side up, unfold a short section of the protective film. Make sure it is smooth and wrinkle-free, and attach the loose end evenly to one of the strips of double-sided tape.

- Continue unrolling the protective film, placing it along the length of the work surface not far from the other double-sided tape.

- Roll up the film and put it on top, over the double-sided tape. Be careful not to pull the originally attached end out of the tape, orient the film so that the film is straight, not wrinkled, and reasonably taut, but not so tight that the film shrinks later. (When the film is stretched during use, the edges have a tendency to pull up as the film tries to return to its original shape.)

- Lower the film onto the second double-sided tape. Using a utility knife, cut the roll from the film that is now waiting to receive the sheet to be protected.

- Place one edge of a piece of material on one end or side of the protective film. Place it where the film is held by the double-sided tape. Gradually place the part on the adhesive film. NOTE: If the material is flexible, roll it up by bending it slightly when you place it on the film, allowing air to escape between the material and the film.

- To ensure that the sheet adheres to the film, apply pressure to the material, especially along all edges, to ensure a good bond. A clean paint roller might work for this purpose.

- Use a utility knife to trace the outline of the part on the protective film, cut off the excess film, delete the excess and process it. Carefully flip the section over, applying direct pressure to the film if needed, working from the center out to ensure good adhesion throughout the area, checking that the finished piece is complete, wrinkle-free coverage.

PE protective film is the simplest polymer organic compound and the most widely used polymer material in the world today.

The adsorption function and application fields of PE protective film:

In the production process of PE protective film, corona treatment is generally carried out, which will increase the surface area of the film and bring static electricity, and then carry out the subsequent gluing work, so that the film and glue can be well combined. .

The PE protective film will be effectively on the inner layer of the film. When it is produced, its main material is EVA, which has a certain adsorption function when it is used, so as to realize the entire adsorption function of the film. The electrostatic formula components of these two kinds of electrostatic films are also different, and the quality and price of the products are also different. The electrostatic film with low price and low grade will transfer the electrostatic components on the surface of the product, resulting in defective and scrapped products.

PE protective film is a common surface protective film in our daily life. Due to its high-quality features such as good adhesion, conformity and no glue residue, it is widely used in mobile phones, notebook computers, TV screen surfaces, lcd screens, etc. field.

In the production process of PE protective film, the processing temperature of the barrel is appropriately increased and the method of polycooling is adopted. The transparency of the film can be improved. In fact, to produce a transparent PP film, a water quenching method must be used. If air cooling is used, the PP blown film produced is fuzzy and translucent due to the poor cooling effect. For this reason, it is an effective way to improve the transparency by appropriately increasing the processing temperature and using high-efficiency cooling methods in production. A small amount of polyacrylate resin with good compatibility and excellent transparency is added to the PE protective film and PP protective film.

Description

| Product | Protective film for color steel plate(PPGI) |

| Backing film | PE |

| Adhesive type | Water-based acrylic |

| Color of film | Customized |

| Application | PPGI |

| Thickness | 25-40microns |

| Width | 1000-1500mm |

| Length | 1000m/roll |

| 180° peel strength | 150g/25mm |

| Elongation at Break MD | ≥300% |

| UV resistance | 45days |

PE Protective Film Mold Cutting Basic Knowledge

- The strength of the surface material of the PE protective film The strength of the surface material is related to the thickness of the surface material, fiber (polymer) structure and its own humidity. In the die-cutting process of PET protective film materials, the most important factor related to the surface material is the waste discharge speed. The higher the humidity, the weaker the strength of the PE protective film manufacturer's material after it is damp, and then it can be pulled off at will, and it is even impossible to discharge waste.

When designing the layout, according to the strength of the material, through the implementation of a reasonable size and speed of the waste removal of the label, how not only can the production efficiency be improved, but also the waste of the material can be increased.

- The thickness of the surface material The thickness of the material directly affects the depth of die-cutting. The thicker the material, the more random die-cutting. Because the thicker the material, the greater the die-cutting tolerance, the smaller the chance of cutting through the bottom paper. Relatively speaking, the material is thin, and the defect of cutting through the bottom paper randomly appears. For example, it can distinguish die-cutting 80g/m2 and 60g/m2 on a flat-bed label die-cutting machine with the same bottom paper. The result found that: 80g/m2 material is normal for die-cutting and waste discharge, but when replaced with 60g/m2 material, waste discharge breakage, bottom paper cut through and loss of standard phenomenon often occur during die-cutting. There are many notices for this kind of situation. Assuming the use of circular die-cutting methods or reducing the die-cutting area, PE protective film use high-precision equipment, etc., this phenomenon can be added or avoided.

Therefore, when die-cutting thin surface materials, you must work with high-precision equipment to increase the die-cutting area as much as possible (especially for small labels).

The Application Field of Protective Film Of Color Steel Plate

Hardware industry: Computer case, galvanized sheet stamping, aluminum plate, stainless steel plate, titanium plate, plastic steel plate, glass plate, solar panel, etc.

Optoelectronic industry: LCD liquid crystal display, backlight panel, cold light film, membrane switch, mobile phone screen, etc.

Plastic industry: ABS, PP injection molding products, PVC sheets, acrylic sheets, instruments, plastic lenses, surface protection of painted parts, etc.

Printing industry: Surface protection of printing nameplates such as PVC, PC board, aluminum plate, film, etc.

Wire and cable industry: Protection of shaft-mounted copper wires, semi-finished products, finished products, and rolled finished products can effectively prevent dust pollution, and have anti-oxidation and anti-dirty effects

Electronics industry: During production, finished products and semi-finished products are generally used to protect the finished products, which are not easy to be scratched and damaged on the assembly line.

Mobile phone digital industry: Mobile phone film, also known as mobile phone beauty film and mobile phone protective film, is a cold film that can be used to install mobile phone body and screen.

FAQ

Hot Tags: protective film of color steel plate, China protective film of color steel plate suppliers, manufacturers