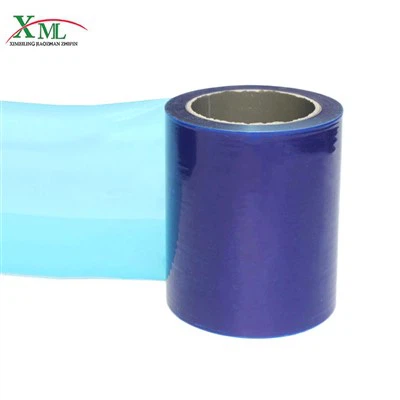

Electrostatic Protective Film

ESD stands for electrostatic discharge, which refers to the phenomenon of electricity building up on human bodies or insulative surfaces and causing disruptive discharges. This phenomenon can damage circuitry, especially that of electronic products, such as PCs and mobile devices.

Wuxi Xi Mei Ling Adhesive Products Co.,Ltd.

Wuxi Xi Mei Ling Adhesive Products Co.,Ltd. is located in the scenic coast of Taihu Lake, the birthplace of national industry and commerce, Jiangnan city of Wuxi. The company was founded in 2001, in the field of adhesive products we have many years of experience in the production of professional enterprises. The company provides a full range of protective film industry chain services, the production of various types of acrylic protective film, glass special protective film, aluminum plastic doors and windows profiles protective film, Stretch film, stainless steel color plate protective film, security door protective film, carpet Floor protective film, building decoration materials protective film, aluminum, household appliances, such as protective film products by all users of praise.

Why Choose US

Professional team

Our professional team collaborate and communicate effectively with one another, and are committed to delivering high-quality results. They are capable of handling complex challenges and projects that require their specialized expertise and experience.

Innovation

We are dedicated to improving our systems continually, ensuring that the technology we offer is always cutting edge.

One stop solution

We can offer a range of services, from consultation and advice to product design and delivery. It is a convenience for the customers, as they can get all the help they need in one place.

24h online service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

Glass Light Adhesive Protective Film

Glass light adhesive protective film When we produce and cut glass, the surface of glass will be scratched, glass light adhesive protective film can help us. It can protect windows, mirrors and high gloss surfaces from moving damage and paint oversprays.

PE Protection Film For Electronics Devices

PE Protection Film For Electronics Devices protects electronic products from scratches, dirt and other damages, avoiding any unnecessary scratches or damages that may occur during transportation or daily use. The film maintains the visual clarity of the device, providing an unobstructed view of the screen while protecting the screen from fingerprints.

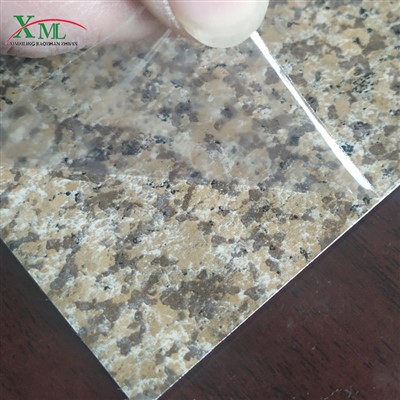

PE Protective Film For Ceramic

PE Protective Film For Ceramic protects marble and tile surfaces from dust, dirt and worker traffic during processing, transport and installation, retaining their original luster and protecting their quality from compromise, increasing customer satisfaction.

Plastic Printe Aluminum Protective Film

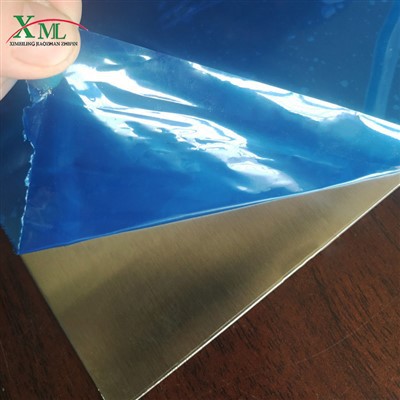

Plastic printe aluminum protective film Aluminum surfaces can be marred by chatter marks, scratches or swirls, or contaminated by overspray, solvents, dust and the like.

Protective Film Of Color Steel Plate

Protective Film Of Color Steel Plate is made of carefully selected high-quality materials, which can effectively protect the surface of color steel plate from scratches, dirt and other forms of damage that may occur during manufacturing, transportation and construction.

PE Protection Film For ABS Acrylic

PE Protection Film For ABS Acrylic is generally used on surfaces sensitive to adhesive or glue residues. Such as glass, lenses, high-gloss plastic surfaces, acrylic and other very smooth surfaces. No static can be felt on the outside of PE Protection Film For ABS Acrylic. It is a low adhesion self-adhesive film.

PE Protective Film For Mirror is very different from other surface protection films. Used on the back of a silver-plated glass mirror, it will not tear after installation, and can provide temporary protection for the mirror during transportation, storage, handling and installation.

Protective Film For Metal Surface

Protective Film For Metal Surface is an excellent way to keep metal surfaces clean, shiny and looking like new. When in use, it acts as a barrier between the metal surface and its environment, protecting it from dust, dirt, scratches and other forms of physical damage.

Metal Aluminum Alloy Stainless Steel Surface Protective Film

Metal Aluminum Alloy Stainless Steel Surface Protective Film Metal aluminum Alloy Stainless Steel surface protective film is dsigned to temporarily protect a variety of metal surfaces. It removes clean, without leaving any residue behind.

What is Electrostatic Protective Film

ESD film is a thin plastic sheet that can be applied to the surface of electronic components i.e. printed circuit boards (PCBs) or used as a secondary packaging material. The film provides electrical protection and plays an important role in preventing electrical shock. ESD stands for electrostatic discharge, which refers to the phenomenon of electricity building up on human bodies or insulative surfaces and causing disruptive discharges. This phenomenon can damage circuitry, especially that of electronic products, such as PCs and mobile devices.

Advantages of Electrostatic Protective Film

Electrostatic Discharge Protection

ESD (Electrostatic Discharge) PET film is designed to provide protection against electrostatic discharge. It is commonly used in various industries, such as electronics manufacturing, where sensitive electronic components can be easily damaged by static electricity. ESD PET film is made by incorporating additives into the PET (polyethylene terephthalate) material during the manufacturing process. These additives help to enhance the film's ability to dissipate static charges, reducing the risk of damage to electronic devices.

Component Protection

ESD PET film not only helps control and dissipate static electricity but also serves as a protective barrier for electronic components. It shields them from potential damage that can occur during various stages, including handling, transportation, and storage. During these stages, electronic components are vulnerable to physical damage, such as scratches, abrasion, or impact. ESD PET film acts as a protective layer, preventing direct contact between the components and external objects or surfaces. It provides a barrier that helps absorb or distribute any mechanical forces, reducing the risk of physical damage.

Transparency and Clarity

PET-based ESD films are known for their high transparency and clarity. This is an important characteristic that allows for easy visual inspection of the protected components without compromising their visibility or readability. In applications where clear visibility is crucial, such as displays and touchscreens, PET-based ESD films offer a solution that maintains optical clarity. The transparency of these films ensures that the protected components can be seen clearly, allowing for visual inspection, quality control, or monitoring of their performance.

Dimensional Stability

Dimensional stability is a crucial characteristic of ESD PET film, ensuring consistent protection for enclosed components and preventing warping or distortion that could potentially affect their functionality. ESD PET film is engineered to maintain its shape and size under varying environmental conditions, including temperature and humidity changes. This means that the film remains stable and does not shrink, expand, or deform significantly, even when exposed to different environmental factors.

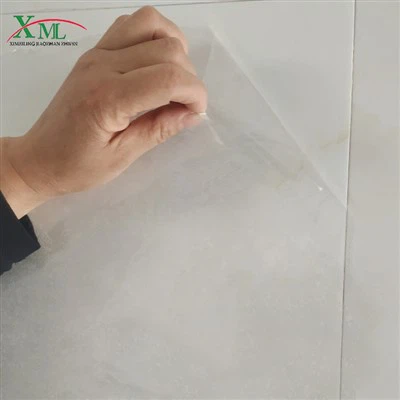

What Are the Characteristics of PE Electrostatic Film

The pe electrostatic film itself does not contain any kind of chemical solvent. It is produced in a 1000-level high-clean dust-free workshop. No matter in the production process or in the future use process, no toxic and harmful substances will be produced.

The surface of the pe electrostatic film has good adsorption, good adhesion, and no residual glue after tearing off, which does not affect the appearance of the product.

Easy to stick and easy to tear, good temperature resistance, no yellowing and overflowing glue, easy to operate and light, safe and environmentally friendly.

Smooth surface, good transparency, no dust spots, uniform thickness

It has good moisture resistance and weather resistance, and can withstand high temperatures of up to 120 degrees, and can be used in high temperature environments.

Electrostatic Protective Film Technical Parameters

| Product Name | Electrostatic protective film |

| Length | 200 M – 1000M |

| Width | 2.6M maximum (slice upon request) |

| Thickness | 40-80 um |

| Adhesion | 1-6g/25mm |

| Manufacturing | 3 layers coextrude blown film |

| Applications | Various Glossy Surface Protection |

The process of applying electrostatic protective film typically involves the following steps:

Clean and prepare the surface

Before applying the protective film, it is important to clean the surface to remove any dirt, dust, or other debris that may interfere with the adhesion of the film. Use a mild solution of soap and water and wipe the surface dry with a lint-free cloth.

Measure and cut the film

Measure the surface to be covered and cut the electrostatic protective film to size using a pair of scissors or a box cutter. Leave a margin of a few millimeters around the edges to ensure complete coverage of the surface.

Apply the film to the surface

Gently apply the electrostatic film to the surface, starting from one edge and working your way across. Smooth out any bubbles or creases as you go, using a credit card or other flat tool to press the film into place.

Trim the excess film

Once the electrostatic protective film is in place, use a sharp blade or other cutting tool to trim away any excess material around the edges.

Inspect the surface

After applying the protective film, inspect the surface for any remaining bubbles or creases. If necessary, carefully lift the edge of the film and reapply it to smooth out any imperfections.

Overall, applying electrostatic protective film is a fairly simple process that can be done with minimal tools and experience. By following these steps, you can ensure that your surfaces are protected from scratches, dust, and other types of damage.

How to Distinguish Between Electrostatic Film and Anti-Static Film

Electrostatic film

The electrostatic film is a non-glued film, does not contain any chemical solvents, is environmentally friendly, does not produce any toxic gas, effectively reduces bad products, and improves product value.

The electrostatic film protects the objects by the electrostatic adsorption of the product itself. It is generally used on surfaces that are sensitive to adhesive or glue residues and is mostly used on very smooth surfaces such as glass, lenses, high-gloss plastic surfaces, and acrylic.

Static electricity is not felt on the outside of the electrostatic film. It is a self-adhesive film with low adhesion and sufficient for high-gloss surfaces.

PE anti-static film

The anti-static film is made by adding imported anti-static agents to the PE raw material to make the surface resistance reach 10-10 Ω. It does not generate static electricity by friction. After high-temperature shaping, it is durable and has a good anti-static effect.

Therefore, the anti-static film has an extra layer of function than the electrostatic film to prevent static electricity from damaging human products and work sites.

The cleanliness of anti-static protective film products is extremely high, and the transparency is excellent, and it has good weather resistance.

Anti-static protective films are generally widely used in the surface material protection and prevention of static electricity in the production process of FPC, PCB, and electronic components.

PE conductive film is also a kind of anti-static film. It is made by adding superconducting nano carbon black material to PE raw material to make its surface resistance reach 10E2~10E5Ω. It does not generate static electricity by friction itself, and it is durable after high-temperature settings. Good antistatic effect.

Therefore, the anti-static film has an extra layer of function than the electrostatic film to prevent static electricity from damaging human products and work sites.

The cleanliness of anti-static protective film products is extremely high, opaque and black, and has good weather resistance.

Conductive electrical protective films are usually widely used in the production of wafers, semiconductors, FPCs, PCBs, and electronic components to protect surface materials and prevent static electricity.

Different Categories of Electrostatic Discharge (ESD) Films Available in the Market

Conductive Electrostatic Discharge (ESD) Films

Conductive ESD films have low electrical resistance, meaning electrons, and hence the electric current, can easily pass through these films. Hence, when an electronic circuit is packaged using a conductive ESD film, instead of passing the electric current onto other circuit, the current passes through the films, thereby avoiding electronic discharge between the two circuits. Since the conduction of electric charge through these films is pretty fast, conductive ESD films can offer a discharge even to the strongest electric currents.

Dissipative Electrostatic Discharge (ESD) Films

Dissipative ESD materials are different from conductive materials as they slow down the flow of electrons to the ground. Thus, the flow of the electric charge is in a controlled manner than that in conductive materials. A unique feature of dissipative ESD films is that they offer protection to the electronic components from the atmospheric moisture. In fact, these films soak in the moisture from the air to form a layer of water molecules over the surface of the film which, in turn, makes it difficult to generate and pass electric current.

Anti-Static Electrostatic Discharge (ESD) Films

Anti-static electrostatic discharge films mainly focus on inhibiting triboelectric charging. Triboelectric charging is a type of static electricity wherein the contact electrification occurs upon separation of two electrically charged objects. Anti-static ESD films are extensively used in the aerospace industry as a protective material to cover and protect sensitive spacecraft components and equipment.

Process Characteristics of Electrostatic Protective Film

Static protection films are an innovation increasingly used to protect surfaces from damage and scratches. These films have a variety of process features that make them unique and suitable for different applications.

First, the electrostatic protective film has electrostatic adhesive properties, making it easy to apply and remove. This means no glue or adhesive is required when applying the film, ensuring that no residue or damage is left on the surface when the film is peeled off. This process makes the electrostatic protective film highly versatile and ideal for a variety of surfaces, including glass, metal and plastic.

Secondly, the electrostatic protective film has high transparency and can retain the color, brightness and visibility of the underlying surface. These films are optimized to reduce light reflection and ensure no loss of transparency when applied. This process means that the electrostatic protective film not only protects, but also enables users to fully enjoy the benefits of the surface material.

Third, static protective films resist damage from a variety of factors, including water, scratches, and UV rays. These films are engineered to protect the underlying surface from environmental factors that can cause damage and reduce the quality of the material. This is an important process that ensures the longevity and durability of the surface and prevents replacement costs.

In summary, electrostatic protective films have a variety of process characteristics, making them suitable for different applications. They are easy to apply and remove, highly transparent, and not easily damaged. These features ensure that the surface is protected, maintains its quality and remains durable. Static protective film is an innovation that offers users countless opportunities to protect and preserve their surfaces, making it a valuable addition to any protective measure.

What Are the Advantages of Electrostatic Protective Film and PVC Protective Film

The electrostatic protective film itself is a kind of non-adhesive film. It can protect the product itself by electrostatic adsorption and sticking to the object. It is mostly used for very smooth surfaces such as glass, lens, high-gloss plastic surface, and acrylic.

The electrostatic protective film does not feel static electricity on the outside. It is a self-adhesive film with low adhesion, which is satisfactory for high-gloss surfaces; the electrostatic protective film, like its name, actually has a very good anti-static and protective function. In the current market The planning of the application will be very extensive, and the most commonly used electrostatic protective films are pe electrostatic protective film and pvc electrostatic protective film.

Then about the product characteristics of PVC protective film in the electrostatic protective film:

- Belongs to PVC calendered products: relatively thin, uniform thickness, excellent flattening;

- The transparency of the product itself is relatively good, the water mark is relatively small, and the crystal points will be relatively small;

- The static resistance value is relatively high, and the electrostatic effect is good.

The viscosity can be adjusted according to customer needs; moreover, it conforms to the national work norms.

There is also a frosted PET protective film, which is suitable for photoelectric film, diffuser, light guide plate, film protection LCD, touch screen, mobile phone, digital camera and PDA screen. It can avoid scratches on the surface of objects during use, and achieve Protect screen effect.

How To Buy PET Electrostatic Film Correctly

The electrostatic adsorption method adopts the principle of physics. When the protective film is in contact with the LCD screen, the pressure in the air between the protective film and the LCD screen becomes smaller, making the atmospheric pressure stronger than the air pressure between the screen and the film. produce adsorption capacity.

The electrostatic film is not only easy to stick but also easy to tear off. When you buy a screen protector, you should not only consider the scratch resistance of the film, but also pay attention to the adsorption property, not electrostatic adsorption.

The electrostatic adsorption screen protectors sold on the market are precisely static electricity + silica gel ion adsorption. The adsorption capacity of the silica gel layer has a great influence on the adsorption performance of the film. The electrostatic adsorption screen protectors of different manufacturers have different technical levels due to the different silica gel layers. The adsorption capacity is also very different, so it is also an electrostatic adsorption screen protector, but the service life of the screen film of different brands is different due to the difference in adsorption.

FAQ

Hot Tags: electrostatic protective film, China electrostatic protective film suppliers, manufacturers